Category

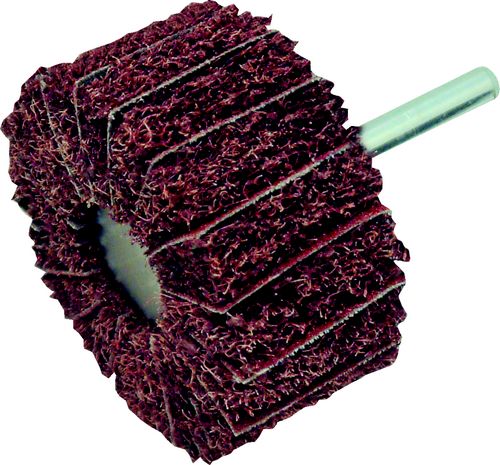

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Blog

Relaunch Promotion

Product Showcase

Filter by Price

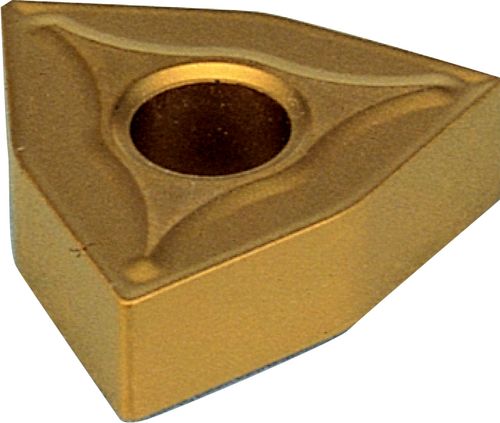

Category: ISO Turning Inserts

ISO Turning Inserts

Showing 97–102 of 102 results

-

WCMX 06T308 INSERT GRADEQZ830Read more

Indexable Turning Inserts – WCMX

Grade description:

QZ820 (ISO P10-P30 M20-M35 K20-K30) General purpose coated grade for Steels and Cast Irons.

QZ830 (ISO P25-P40) Tough coated grade for Steels, suitable for interrupted cutting such as cross holes. -

WCMX 080412 INSERT GRADEQZ830Read more

Indexable Turning Inserts – WCMX

Grade description:

QZ820 (ISO P10-P30 M20-M35 K20-K30) General purpose coated grade for Steels and Cast Irons.

QZ830 (ISO P25-P40) Tough coated grade for Steels, suitable for interrupted cutting such as cross holes. -

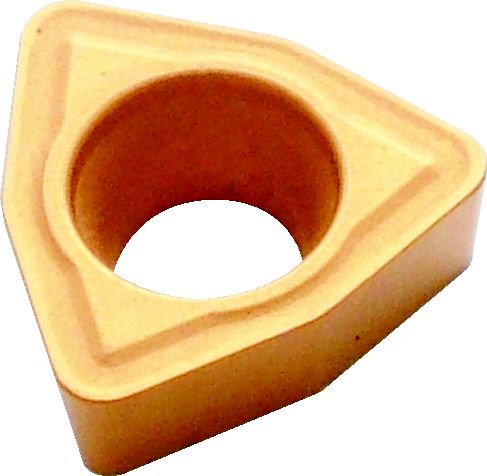

WNMG 060404-NM4 INSERT GRADE QX520Rp182.000Read more

Indexable Turning Inserts – WNMG

Grades:

QX500 (ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

QX510 (ISO P01-P15 M10-M15 K01-K20) Coated. Used for finishing on Steels and Stainless Steels, suitable also for turning Cast Irons including Malleable irons at high speeds.

QX520 (ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

QX5030 (ISO P20-P40 M20-M30) CVD Coated. – Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

QX8010 (ISO M10 S10) Coated. Excellent grade giving superior results on heat resistant super alloys, especially for the aerospace industry. TiAln based coating ensures high wear resistance on these demanding materials.Chip Breaker: NF3. Application: Finish.

Chip Breaker: NSA. Application: Light Cut.

Chip Breaker: NSS. Application: Light/Medium.

Chip Breaker: NM4. Application: Med Cut.

Chip Breaker: NM5. Application: Med Cut.

Chip Breaker: NM6. Application: Med Cut.

Chip Breaker: NR8. Application: Rough. -

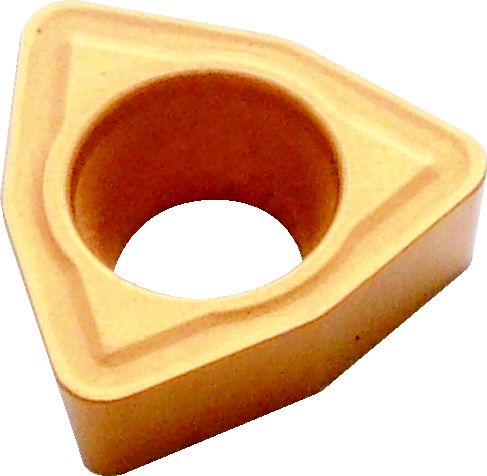

WNMG 060408-NSS INSERT GRADE QX8010Rp182.000Add to cart

Indexable Turning Inserts – WNMG

Grades:

QX500 (ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

QX510 (ISO P01-P15 M10-M15 K01-K20) Coated. Used for finishing on Steels and Stainless Steels, suitable also for turning Cast Irons including Malleable irons at high speeds.

QX520 (ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

QX5030 (ISO P20-P40 M20-M30) CVD Coated. – Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

QX8010 (ISO M10 S10) Coated. Excellent grade giving superior results on heat resistant super alloys, especially for the aerospace industry. TiAln based coating ensures high wear resistance on these demanding materials.Chip Breaker: NF3. Application: Finish.

Chip Breaker: NSA. Application: Light Cut.

Chip Breaker: NSS. Application: Light/Medium.

Chip Breaker: NM4. Application: Med Cut.

Chip Breaker: NM5. Application: Med Cut.

Chip Breaker: NM6. Application: Med Cut.

Chip Breaker: NR8. Application: Rough. -

WNMG 080404-NM5 INSERT GRADE QX520Read more

Indexable Turning Inserts – WNMG

Grades:

QX500 (ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

QX510 (ISO P01-P15 M10-M15 K01-K20) Coated. Used for finishing on Steels and Stainless Steels, suitable also for turning Cast Irons including Malleable irons at high speeds.

QX520 (ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

QX5030 (ISO P20-P40 M20-M30) CVD Coated. – Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

QX8010 (ISO M10 S10) Coated. Excellent grade giving superior results on heat resistant super alloys, especially for the aerospace industry. TiAln based coating ensures high wear resistance on these demanding materials.Chip Breaker: NF3. Application: Finish.

Chip Breaker: NSA. Application: Light Cut.

Chip Breaker: NSS. Application: Light/Medium.

Chip Breaker: NM4. Application: Med Cut.

Chip Breaker: NM5. Application: Med Cut.

Chip Breaker: NM6. Application: Med Cut.

Chip Breaker: NR8. Application: Rough. -

WNMG 080408-NM6 INSERT GRADE QX5030Rp227.000Read more

Indexable Turning Inserts – WNMG

Grades:

QX500 (ISO P10-P25) Cerment. For high speed finishing and light cutting. Will remain a high class surface finish. Mainly used on steels and can be applied to finish some Stainless steels and Cast Irons.

QX510 (ISO P01-P15 M10-M15 K01-K20) Coated. Used for finishing on Steels and Stainless Steels, suitable also for turning Cast Irons including Malleable irons at high speeds.

QX520 (ISO P10-P35 M10-M30 K10-K30) Coated. An excellent general purpose grade for medium roughing on Steels, Stainless and Cast Irons.

QX5030 (ISO P20-P40 M20-M30) CVD Coated. – Medium / rough turning and intermediate cutting of steel / stainless steel. Combination of toughest substrate and alumina coating (MT-TiCN + TiC + AL2O3 + TiN) having superior chipping resistance provide wide coverage.

QX8010 (ISO M10 S10) Coated. Excellent grade giving superior results on heat resistant super alloys, especially for the aerospace industry. TiAln based coating ensures high wear resistance on these demanding materials.Chip Breaker: NF3. Application: Finish.

Chip Breaker: NSA. Application: Light Cut.

Chip Breaker: NSS. Application: Light/Medium.

Chip Breaker: NM4. Application: Med Cut.

Chip Breaker: NM5. Application: Med Cut.

Chip Breaker: NM6. Application: Med Cut.

Chip Breaker: NR8. Application: Rough.