Category

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Archives: Products

Showing 18993–19008 of 23773 results

-

M20 x 70 SKT HEAD C/SUNK SCREW (10.9)Read more

Socket Head Countersunk Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 10.9.

Suitable for all high tensile applications. Maximum operating temperature (unplated): 300°C. For applications that require a flush finished surface. Precisely controlled countersink angle allows maximum flushness and sidewall contact.

Dimensions to DIN7991 -

M20 x 70 SKT HEAD CAP SCREW (12.9)Read more

Socket Head Cap Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 12.9. Suitable for all high tensile

applications. Maximum operating temperature (unplated): 300°C.

Dimensions to BS EN ISO 4762 DIN 912 -

M20 x 75 SKT HEAD CAP SCREW (12.9)Read more

Socket Head Cap Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 12.9. Suitable for all high tensile

applications. Maximum operating temperature (unplated): 300°C.

Dimensions to BS EN ISO 4762 DIN 912 -

M20 x 80 SKT HEAD C/SUNK SCREW (10.9)Read more

Socket Head Countersunk Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 10.9.

Suitable for all high tensile applications. Maximum operating temperature (unplated): 300°C. For applications that require a flush finished surface. Precisely controlled countersink angle allows maximum flushness and sidewall contact.

Dimensions to DIN7991 -

M20 x 80 SKT HEAD CAP SCREW (12.9)Read more

Socket Head Cap Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 12.9. Suitable for all high tensile

applications. Maximum operating temperature (unplated): 300°C.

Dimensions to BS EN ISO 4762 DIN 912 -

M20 x 90 SKT HEAD C/SUNK SCREW (10.9)Read more

Socket Head Countersunk Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 10.9.

Suitable for all high tensile applications. Maximum operating temperature (unplated): 300°C. For applications that require a flush finished surface. Precisely controlled countersink angle allows maximum flushness and sidewall contact.

Dimensions to DIN7991 -

M20 x 90 SKT HEAD CAP SCREW (12.9)Read more

Socket Head Cap Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 12.9. Suitable for all high tensile

applications. Maximum operating temperature (unplated): 300°C.

Dimensions to BS EN ISO 4762 DIN 912 -

M20.0x2.50 GO & NO GO SCREW PLUG GAUGERead more

Kennedy Screw Plug Gauges – Metric Coarse: Double-Ended Go & No Go

Metric Coarse: Double-Ended Go & No Go â Class 6H Tolerance

Made from the finest quality steel and are thoroughly hardened, stabilised and thread ground under strict quality control procedures ensuring a high quality product and Âoptimum wear life. -

M20x2.5 HSS-COBALT BLACKRING SP/FL DIN 376 TAPRead more

Spiral Flute

ISO Metric – Spiral Flute

For blind holes. Taper lead to DIN form C. Tapping tolerance to 6H.The unique general purpose properties of these taps guarantee high productivity by reducing the amount of time spent changing taps for different materials and at the same time reduces the number of taps required by the machine shop.

Swiss+Tech âBlack Ringâ machine taps with their wide range of applications are the result of years of experience in metal cutting. Responsible for our developments were the following demands from our main customers:

⢠Increase of a tapâs versatility.

⢠Reducing the confusing type variety.

⢠Reducing the storage costs for the tools.

⢠Reducing the tool changing times.

For general tapping applications. For production tapping of specific materials a specialist tap may be more suitable. Manufactured to DIN 371/376.The tool geometry (with up to 138 parameters) has been developed and optimised during long-term tests in co-operation with users for the different sections of structural steel, aluminum casting, machining steel, VA-steels, heat-resistant steels and tool steels. Selected hard coatings increase the range of applications. The objective of developing Swiss+Tech’s âBlack Ringâ Taps was the realisation of narrower tolerances and more efficient cutting times for the thread production.

-

M20x2.5 HSS-COBALT BLACKRING SP/PT DIN 376 TAPRead more

HSS-E ‘Black Ring’ Taps

The unique general purpose properties of these taps guarantee high productivity by reducing the amount of time spent changing taps for different materials and at the same time reduces the number of taps required by the machine shop.

Swiss+Tech âBlack Ringâ machine taps with their wide range of applications are the result of years of experience in metal cutting. Responsible for our developments were the following demands from our main customers:

⢠Increase of a tapâs versatility.

⢠Reducing the confusing type variety.

⢠Reducing the storage costs for the tools.

⢠Reducing the tool changing times.

For general tapping applications. For production tapping of specific materials a specialist tap may be more suitable. Manufactured to DIN 371/376.The tool geometry (with up to 138 parameters) has been developed and optimised during long-term tests in co-operation with users for the different sections of structural steel, aluminum casting, machining steel, VA-steels, heat-resistant steels and tool steels. Selected hard coatings increase the range of applications. The objective of developing Swiss+Tech’s âBlack Ringâ Taps was the realisation of narrower tolerances and more efficient cutting times for the thread production.

-

M20x2.50mm 3MT ARBOR FORJSN20 TAPPERRead more

Indexa-Seiki Arbors

Precision machined, fully hardened & ground to give maximum surface contact.

To suit Indexa-Seiki tapping heads. -

M20x2.50mm 4MT ARBOR FORJSN20 TAPPERRead more

Indexa-Seiki Arbors

Precision machined, fully hardened & ground to give maximum surface contact.

To suit Indexa-Seiki tapping heads. -

M20x2.50mm CHASER DIE 20mm D/HD TYPE S20Read more

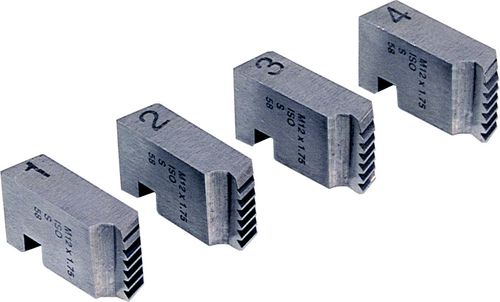

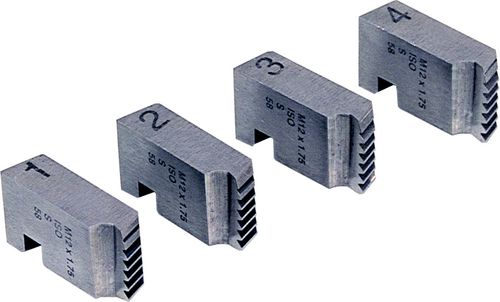

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die. -

M20x2.50mm CHASER DIE 25mm D/HD TYPE S20Read more

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die. -

M20x2.50mm CHASER DIE 32mm D/HD TYPE S20Read more

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die. -

M24 x 100 SKT HEAD CAP SCREW (12.9)Read more

Socket Head Cap Screws: ISO Metric – Standard (Self-Colour)

High Grade Alloy Steel to BS EN ISO 898/1 Grade 12.9. Suitable for all high tensile

applications. Maximum operating temperature (unplated): 300°C.

Dimensions to BS EN ISO 4762 DIN 912