Category

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Blog

Relaunch Promotion

Product Showcase

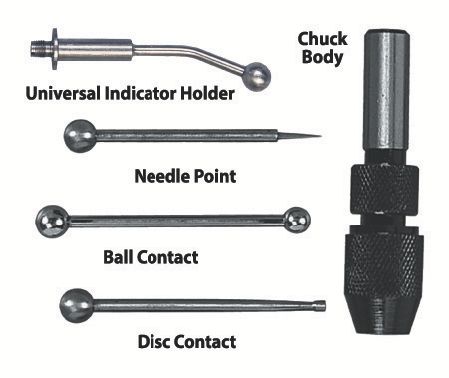

EDGE & CENTRE FINDER SET(5-PCE)

Kennedy Edge & Centre Finder – 5 Piece Set

Consists of a chuck body and four contact arms. Designed to check ârun-outâ or concentricity, straightness and alignment. Will indicate the position of a datum point on a component or fixture from the centre line of a machine spindle. Suitable for use on drill presses, lathes, milling machines, borers etc.

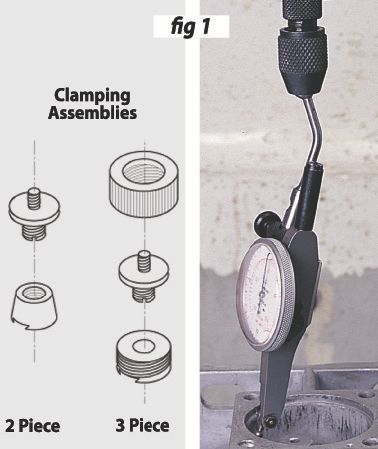

Chuck Body:

Held in the spindle using a suitable drill chuck or collet chuck (fig 1). The contact arms are retained in position using the knurled collar which lightly clamps the ball joint inside the body. Arms may be exchanged without the need to remove the body from the machine spindle.

Universal Indicator Holder

The detachable end will allow clamping with 2 and 3 piece dovetail clamping assemblies and when removed will fit standard 1/4â side clamp. This uses the spindle centre line to align component bores or spigots, check the flatness or squareness of workpieces or fixturing and check run-out of components. The spindle should only be rotated manually to avoid damaging the dial test indicator (fig 1).

Needle Point

To lightly mark out lines and positions on a component as a guide to subsequent operations, using the machineâs dials or digital read-out to position the scriber point (not illustrated).

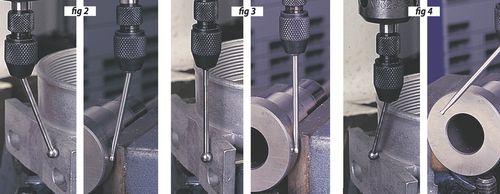

Position the contact arm in line, but slightly away from the surface to be aligned. When finding the surface of a diameter, the âDisc’ must be positioned as near to the centre of that diameter as possible. Run the spindle between 200 and 500 revs/min. The table or spindle is then moved slowly, to bring the contact arm closer to the surface to be aligned. The contact arm will tap lightly against the surface (fig 2) the movement of the arm will become less and less the nearer the datum point gets to the spindle centre line (fig 3). When the arm stops spinning in a straight line and starts to ‘jump’, this indicates the datum point (fig 4):

1/2 contact dia + Edge = Centre

1/2 contact dia – Centre = Edge

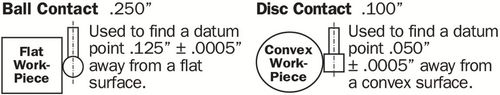

Ball Contact .250â

Used to find a datum point .125â ± .0005â away from a flat surface.

Disc Contact .100â

Used to find a datum point .050â ± .0005â away from a convex surface.

Contents: Chuck Body, Universal Indicator Holder, Needle Point, Ball Contact, Disc Contact.

Out of stock

SKU : KEN5181500K

Kennedy Edge & Centre Finder – 5 Piece Set

Consists of a chuck body and four contact arms. Designed to check ârun-outâ or concentricity, straightness and alignment. Will indicate the position of a datum point on a component or fixture from the centre line of a machine spindle. Suitable for use on drill presses, lathes, milling machines, borers etc.

Chuck Body:

Held in the spindle using a suitable drill chuck or collet chuck (fig 1). The contact arms are retained in position using the knurled collar which lightly clamps the ball joint inside the body. Arms may be exchanged without the need to remove the body from the machine spindle.

Universal Indicator Holder

The detachable end will allow clamping with 2 and 3 piece dovetail clamping assemblies and when removed will fit standard 1/4â side clamp. This uses the spindle centre line to align component bores or spigots, check the flatness or squareness of workpieces or fixturing and check run-out of components. The spindle should only be rotated manually to avoid damaging the dial test indicator (fig 1).

Needle Point

To lightly mark out lines and positions on a component as a guide to subsequent operations, using the machineâs dials or digital read-out to position the scriber point (not illustrated).

Position the contact arm in line, but slightly away from the surface to be aligned. When finding the surface of a diameter, the âDisc’ must be positioned as near to the centre of that diameter as possible. Run the spindle between 200 and 500 revs/min. The table or spindle is then moved slowly, to bring the contact arm closer to the surface to be aligned. The contact arm will tap lightly against the surface (fig 2) the movement of the arm will become less and less the nearer the datum point gets to the spindle centre line (fig 3). When the arm stops spinning in a straight line and starts to ‘jump’, this indicates the datum point (fig 4):

1/2 contact dia + Edge = Centre

1/2 contact dia – Centre = Edge

Ball Contact .250â

Used to find a datum point .125â ± .0005â away from a flat surface.

Disc Contact .100â

Used to find a datum point .050â ± .0005â away from a convex surface.

Contents: Chuck Body, Universal Indicator Holder, Needle Point, Ball Contact, Disc Contact.

Specification :

Brand : Kennedy Industrial

Contents : As Above

eCl@ss Code : 23049190

Overall Depth : 14

Overall Length : 135

Overall Weight : 0.105

Overall Width : 124

UNSPSC Code : 23153013

Weight each : 130g

| Weight | 1 kg |

|---|

Related products

-

TOP BLADE FOR ATL448-3000K SHEARRead more

Replacement Parts for Bench Shears

Spare blades to suit Atlas Bench Shears

-

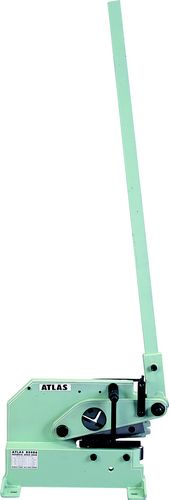

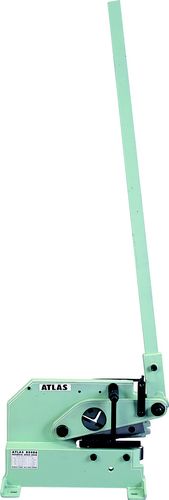

BS406 INDUSTRIAL BENCH SHEARRead more

Atlas Bench Shears

Hand operated, compound lever action bench shears. Capable of rapidly cutting through metal plate, strip and bar. Solid steel frame for rigidity and strength. With hardened and precision ground blades for accurate cutting. Adjustable blade guard.

-

BS120 INDUSTRIAL BENCH SHEARRead more

Atlas Bench Shears

Hand operated, compound lever action bench shears. Capable of rapidly cutting through metal plate, strip and bar. Solid steel frame for rigidity and strength. With hardened and precision ground blades for accurate cutting. Adjustable blade guard.

-

FISH 2000 SAFETY KNIFEAdd to cart

Fish 2000 Safety Knife

The Avon⢠Fish 2000 safety knife has an enclosed blade within a 4.7mm gap and an auto-retracting hook blade, to ensure maximum user safety and to reduce accidental damage to the product in the carton being opened. It is suitable for both left and right-handed users.

Overall length: 155mm.